The Key to Long-Lasting Performance.

CHAT WITH US NOW!! Call now!Our customers

Reduced temperature by over 20%!

“I’ve tried many methods, but this one really helped me. The team worked very fast, and after the cleaning, my system’s temperature dropped by more than 20%!”

Incredible results!

“This helped me so much! Only two people were needed, and even though my work is at high altitudes, the process was super easy. The results were unbelievably good!”

Only 2 hours of cleaning!

“Normally, when my staff cleans it manually, it takes one to two days. But with this, it only took 2 hours! I was able to reduce downtime by 70-80%!”

Give it a try!

“At first, I wasn’t sure if it would clean properly, but after using it, my boat could go back and forth twice without overheating at all. I feel so relieved!”

Scale Buildup?

We’ve Got the Solution!

Choose the Best Option for Your Needs!!

Services

Rental

Get Your Own

Our works

Q&A

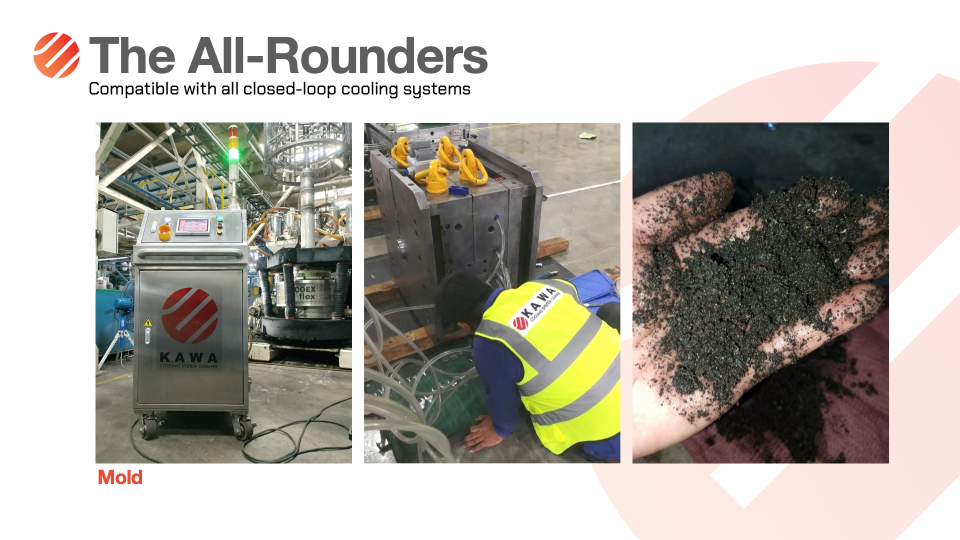

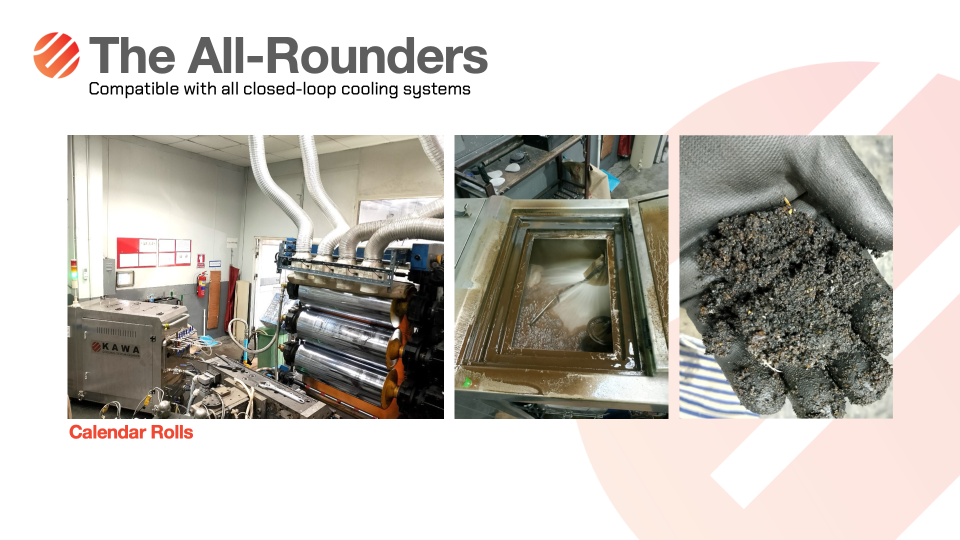

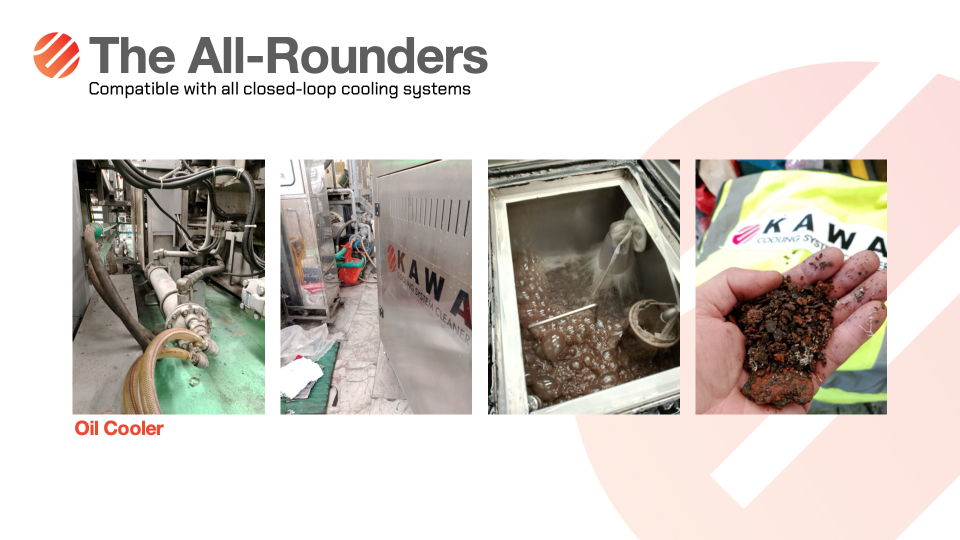

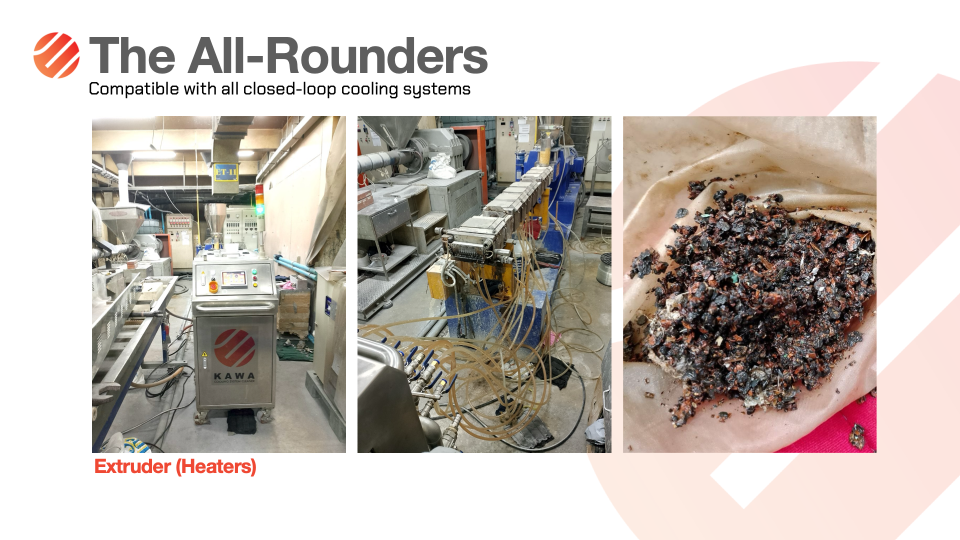

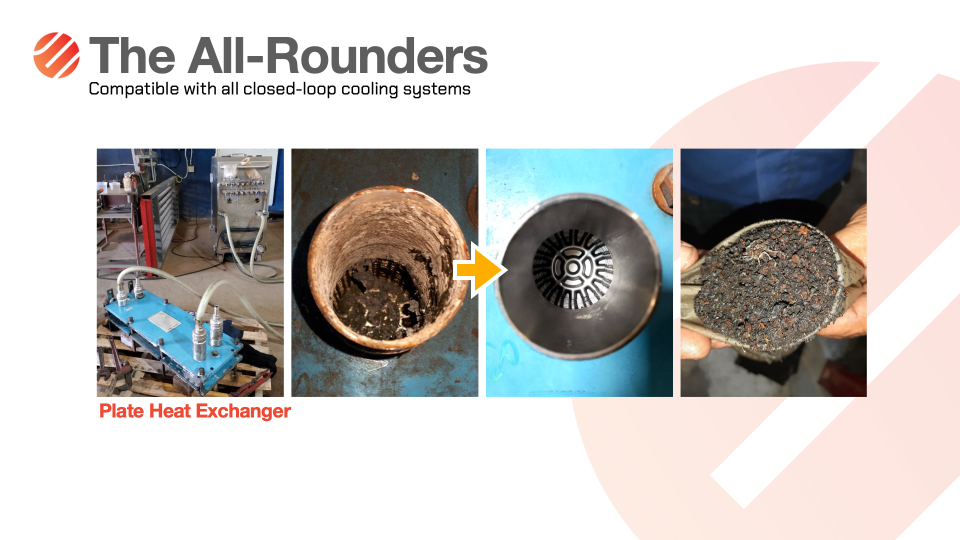

It can be used for equipment and machinery with closed cooling water/heat exchange systems and a water capacity

in the pipes not exceeding 100 liters, such as oil coolers, heat exchangers, molds, extruders, bearings, chillers, roll calendars, kneaders, etc.

There is no need to use chemicals to remove scale with the KAWA machine, so there is no corrosion of pipes, seals, or hoses, and you

don’t have to worry about disposing of hazardous chemicals.

Descaling with the KAWA machine is a flow-in, flow-out process that does not damage hard metal piping systems. However, you should check if the cooling system has any flexible hoses and if they can withstand a water pressure of 5 bar and an air pressure of 9 bar.

After each descaling, the machine stores detailed flow rate data before and after cleaning for comparison and to conclude how much the flow rate has increased. You can also check the sediment and scale that have come out in the filter bag.

Before cleaning, the KAWA machine has a leak detection function. If an alert is issued, cleaning cannot be performed and the leak must be repaired first.

If there is a complete blockage and water or air cannot pass through, cleaning cannot be done. Therefore, it is recommended to plan descaling at least every 6 months to prevent scale problems.

Yes, because when the scale is removed, the cooling efficiency will return to near its original level, without the need to frequently incur the cost of purchasing new equipment.